When you think about what keeps a car running efficiently, your mind might jump to the engine, the transmission, or the tires. However, countless unseen components work tirelessly to ensure your vehicle performs at its best. One of these unsung heroes is filter foam. This specialized material plays a crucial role in protecting vital systems, enhancing performance, and ensuring a clean environment both inside and outside the vehicle.

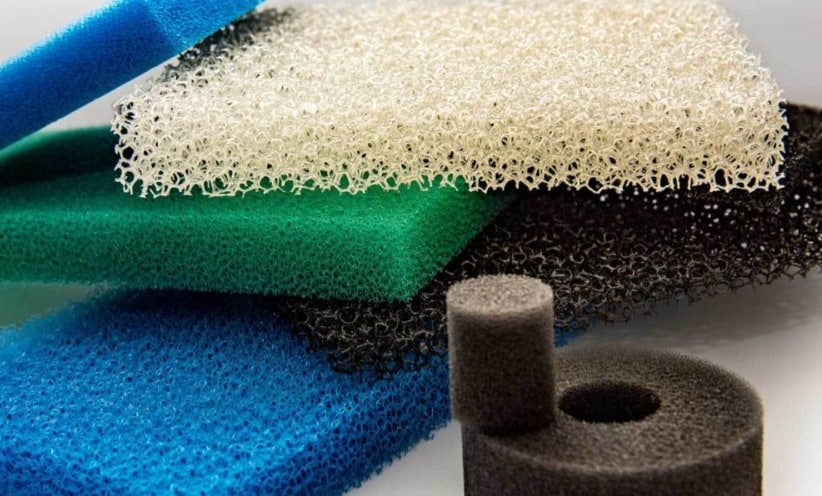

Filter foam is a porous, open-cell material, typically made from polyurethane, engineered to capture and retain particles of various sizes. Its intricate, web-like structure allows air or fluids to pass through while trapping contaminants like dust, pollen, dirt, and debris. In the automotive world, this functionality is essential. From the air your engine breathes to the fuel it consumes, effective filtration is non-negotiable for longevity and optimal operation. Without it, sensitive components would quickly become clogged and damaged, leading to costly repairs and reduced efficiency. Pusponge manufacturer is playing important role in filter foam production for automobiles.

Types of Automotive Filter Foam

Not all filter foam is created equal. The automotive industry primarily utilizes two main types of polyurethane foams, each suited for different applications based on its unique properties.

Polyether Foam: This type is highly resistant to water and humidity, making it an excellent choice for applications exposed to moisture. It offers great durability and flexibility, and it won’t break down when in contact with water. This makes it ideal for cabin air filters and other components that might encounter damp conditions.

Polyester Foam: Known for its superior strength and resistance to oils and fuels, polyester foam is the go-to material for engine-related filtration. It can withstand the harsh chemical environment found under the hood, effectively filtering fuel and oil without degrading. Its structure is also very effective at capturing finer particles.

These foams are further categorized by their pores per inch (PPI), which determines the size of the particles they can trap. A lower PPI indicates larger pores for capturing bigger debris, while a higher PPI means smaller, denser pores for fine filtration.

The Benefits of Using Filter Foam

Integrating filter foam into vehicle design offers a host of advantages. One of the most significant is improved engine performance and longevity. Engine air filters made from foam ensure that only clean air enters the combustion chamber, preventing abrasive particles from causing wear and tear on cylinders and pistons. Similarly, fuel filter foams keep injectors and pumps free from contaminants, ensuring a smooth and efficient fuel supply.

Another key benefit is enhanced passenger comfort. Cabin air filters, often made of polyether foam, trap dust, pollen, and other allergens, preventing them from entering the vehicle’s interior. This creates a healthier and more pleasant environment for the driver and passengers, which is especially important for those with allergies or respiratory sensitivities. Furthermore, foam is a cost-effective and versatile material, allowing manufacturers to design custom filtration solutions for a wide range of needs.

Applications Throughout the Vehicle

Filter foam is found in more places than you might expect. Its versatility allows it to be used in various critical components:

Engine Air Intake Filters: This is perhaps the most well-known application. Foam filters provide excellent airflow while trapping harmful contaminants.

Fuel Filters: Polyester foam is used to filter impurities from gasoline or diesel before it reaches the engine.

Cabin Air Filters: These improve air quality inside the car by filtering out pollutants from the outside air.

Oil Filters: Foam can be used as a medium to trap sludge and particles in engine oil, keeping the engine lubricated properly.

Small Engine Filters: Lawn mowers, motorcycles, and other vehicles with small engines heavily rely on foam filters for protection.

Innovations in Filter Foam Technology

The world of filter foam is not static. Researchers and engineers are constantly developing new technologies to improve performance. One major advancement is the creation of multi-layered or dual-stage foams. These filters combine layers with different PPI ratings, allowing them to capture a broader range of particle sizes more effectively—trapping larger debris in the outer layer and finer particles in the inner layer.

Additionally, antimicrobial treatments are now being applied to cabin air filters. These treatments help prevent the growth of mold and bacteria on the filter itself, further improving the air quality inside the vehicle. The push for more sustainable and recyclable materials is also influencing foam production, with a growing focus on developing eco-friendly alternatives.

In conclusion, filter foam is a fundamental material in the modern automotive industry. From protecting the engine to ensuring clean cabin air, its role is both diverse and critical. As vehicle technology continues to advance, so too will the foams designed to protect them, ensuring our cars run cleaner, last longer, and provide a safer, more comfortable experience for years to come.