Material handling equipment has undergone rapid evolution over recent decades to accommodate the growing complexity and pace of modern industrial operations. As facilities expand and businesses contend with larger volumes, the demand for reliable, long-lasting components has never been higher. At the heart of this evolution, the phenolic wheel stands out as a technology that masterfully combines strength, efficiency, and technical adaptability. Not only do phenolic wheels enhance the performance and reliability of essential transport and handling systems, but they also enable businesses to minimize costly downtime by ensuring that key equipment remains operational for longer periods. As a result, companies can optimize productivity and operational safety in increasingly competitive markets.

Also Read: What’s Included in a Professional HVAC Tune-Up?

Phenolic wheels have become an industry standard due to their exceptional durability, longevity, and operational safety, making them ideal for demanding environments. Designed for logistics and material handling, these wheels help reduce maintenance costs and operational interruptions, facilitating continuous workflow in warehouses and manufacturing settings. Their advanced engineering enables facility managers to select optimal equipment for specific needs, enhancing workplace safety and productivity while supporting sustainable growth. As businesses focus on efficiency, phenolic wheels provide reliable solutions that offer long-term value, encompassing cost savings, sustainability, and ease of maintenance.

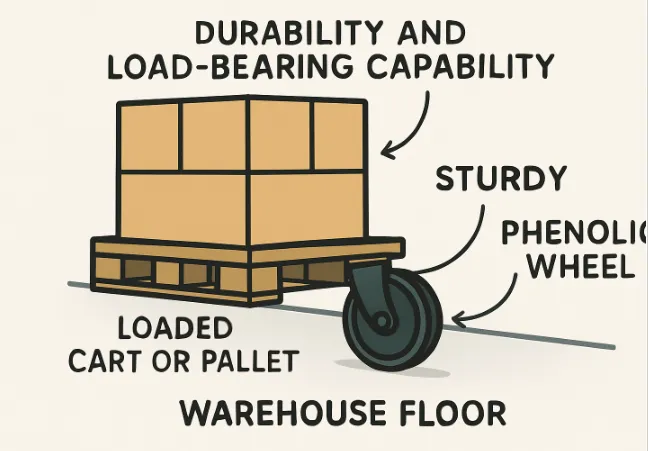

High Load Capacity

One of the defining features of phenolic wheels is their remarkable capacity to support significant weight without suffering from structural failure or deformation. Constructed from phenolic resin and featuring embedded reinforcement fibers, these wheels are specifically designed for high-load scenarios where durability is essential. Their unique internal structure delivers an impressive strength-to-weight ratio, allowing manufacturers to transport heavy pallets, sizable pieces of machinery, or bulk equipment, all with minimal risk of wheel collapse or rapid wear. This inherent sturdiness improves employee safety by reducing the possibility of sudden mechanical failures, thereby safeguarding both the goods and the personnel handling them. This makes phenolic wheels an indispensable component in applications requiring consistent heavy lifting, and an obvious choice over less durable wheel types that are prone to more frequent breakdowns or catastrophic failures in high-stress environments.

Chemical Resistance

In industrial settings, handling equipment is often exposed to a variety of harsh chemicals, oils, greases, and cleaning agents. Phenolic wheels are engineered to resist most chemical exposures, allowing them to maintain their structural integrity and function even in environments where corrosion and degradation are ongoing risks. This resistance not only translates into longer component life but also greatly reduces the lifetime costs associated with frequent repairs or replacements. Additionally, their resilience makes them an excellent option for facilities where chemical spills or leaks are a known hazard. However, it is vital to note that, like many engineered products, continuous submersion or excessive exposure to water can gradually degrade the wheel’s resin composition, potentially reducing its effectiveness. As such, facility managers should avoid using phenolic wheels in applications that involve constant wetness to maximize their utility.

Temperature Toleraequipment is commonly utilized in industrial environments subject to significant temperature fluctuations, ranging from deep freezers and cold storage facilities to baking ovens and foundries. Phenolic wheels are uniquely equipped to handle these extremes, providing reliable service life in conditions ranging from -50°F to well over 250°F, and with certain advanced wheels, up to a blistering 475°F. Their resistance to deformation or failure under rapid temperature shifts ensures smooth operation where other types of wheels may soften, crack, or otherwise fail. This makes phenolic wheels essential in industries such as food processing, chemical manufacturing, and metalworking, where uninterrupted mobility and reliability are necessary despite hostile or cyclical temperature environments. For more detailed information about best practices and material selections in high-temperature environments, the Durastar Casters resource on high-temperature phenolic wheels offers helpful industry insights that complement the use of phenolic wheels.

Floor Protection

Despite their strength, phenolic wheels are also designed to minimize floor damage, a crucial consideration when facility surfaces must be protected to maintain warranties and avoid costly restoration. Their non-marking and smooth, solid construction helps prevent scratching, gouging, or streaking on sealed concrete, tile, or epoxy-coated floors. This feature is particularly beneficial in distribution centers, laboratories, or grocery storage areas, where both heavy loads and premium flooring meet. Compared to metallic wheels, which can generate excessive noise and abrasion, phenolic wheels offer quieter operation, reducing noise pollution and helping to create a safer, more comfortable working environment. In the long run, the use of these wheels can save significant amounts in floor maintenance and minimize disruptions arising from floor repair projects.

Cost-Effectiveness

One of the defining advantages of phenolic wheels is their affordability, especially when compared to wheels made from solid steel or high-performance polymers. Despite their lower price point, they still offer impressive strength, resilience, and dependability over extended periods of use. For companies managing warehouses, factories, or facilities that require dozens or even hundreds of wheels, the cost savings associated with choosing phenolic wheels can be substantial. These cost benefits should not be mistaken for low quality; instead, phenolic wheels deliver premium strength and extended lifespan at a fraction of the investment. Facility managers striving to control budgets without sacrificing reliability naturally gravitate toward phenolic wheels as a proven solution for balancing performance and price, aiding in keeping operational costs manageable over time.

Applications in Various Industries

Thanks to their robust construction, chemical resistance, and ability to perform over a diverse range of temperatures, phenolic wheels find indispensable applications across a wide variety of industries. For example, in bustling warehouses, they facilitate the rapid movement of heavy goods and pallets while offering enough durability to survive accidental impacts and continued use. On dynamic manufacturing floors, phenolic wheels enable operators to reposition machinery or transfer materials efficiently, maintaining production lines’ agility and productivity. In automotive facilities, these wheels support the movement of parts, tools, and assemblies across large spaces, where reliability is crucial to maintaining uptime and meeting production targets. Even within institutional settings, such as hospitals, schools, and research laboratories, phenolic wheels prove their worth by supporting durable, low-maintenance carts, stands, or equipment that must be moved regularly without leaving floor marks or generating disruptive noise. Ultimately, the versatility and performance of phenolic wheels make them a top-tier choice in any industry where workflow continuity, equipment reliability, and floor protection are critical to mission success.

Maintenance and Longevity

One of the often-overlooked advantages of phenolic wheels is their minimal maintenance requirements, which directly lead to a longer service life and reduced upkeep costs. Facility teams typically only need to conduct routine inspections to check for visible wear or accumulated debris. In dry environments, these wheels can function optimally for extended periods with only regular cleaning and periodic checks for signs of damage. When longevity and operational reliability are top priorities, the superior lifespan of phenolic wheels provides a strong return on investment, keeping equipment available and minimizing downtime-related disruptions. For facility professionals seeking to extend the usable lifespan of their material handling equipment, the Caster Connection guide provides practical maintenance tips applicable to a wide range of wheeled equipment, including those utilizing phenolic wheel systems.

Conclusion

In summary, phenolic wheel technology offers a smart and effective solution for meeting the demands of modern material handling environments. Their exceptional combination of high load capability, impressive chemical and temperature resistance, floor friendliness, and cost-effectiveness marks them as a staple of high-performance industrial operations. The widespread adoption of phenolic wheels across multiple industries serves as a testament to their reliability and value, helping organizations to achieve efficient workflows, prolong equipment lifespan, and reduce ongoing costs. By investing in phenolic wheels, companies not only secure operational continuity and protect their infrastructure but also ensure that their teams can perform safely and with confidence in every shift.